The Purpose of LapidarySlab.com

Managing our continually expanding inventory has become increasingly complex over time. This website was developed to provide a comprehensive catalog of our lapidary slabs and rough, as well as a resource for sharing relevant information with our visitors.

We do not offer products for sale at this time.

Main Lapidary Slab & Rough Categories

Our Latest Slabs & Rough

-

Mushroom Jasper

-

Mexican Purple Chalcedony Rough

-

Utah Red Jasper Rough

-

Mookaite Jasper Rough

-

Turritella Agate Rough

-

Petrified Wood Moss Agate Rough

-

Purple Chalcedony Rough

-

Youngite Specimen

-

Marysvale Rhyolite Rough

-

Optically Clear Quartz Rough

-

Unknown Plume Agate Rough

-

St. John’s Petrified Wood Specimen

What are lapidary Slabs?

Unpolished slabs of rock or minerals, referred to as lapidary slabs, are employed for lapidary projects such as cabochon creation, carving, tumbling, faceting, napping, and other stonework. They may be polished for display purposes.

Slab Thickness

The standard thickness for cutting slabs is approximately 1/4″, however, they may be cut to varying thicknesses depending on the desired outcome.

Cutting slabs thinner reduces a final cabochon’s thickness, ideal for earrings or pendants where weight is a factor.

Thicker slabs are occasionally cut to create a cabochon with an exceptionally high dome, especially useful for translucent materials to permit ample light penetration.

Why purchase lapidary slabs?

Expense of cutting slabs

Acquiring slabs offers several benefits over purchasing rough materials and cutting them oneself, as lapidary equipment, including saws and blades, can be costly, with saws ranging into the thousands and blades reaching hundreds of dollars.

For tasks like cabbing, napping, or carving, small trim saws provide and affordable means to cut slabs into specific shapes, although they are not suited for cutting slabs.

Financial risk of cutting slabs

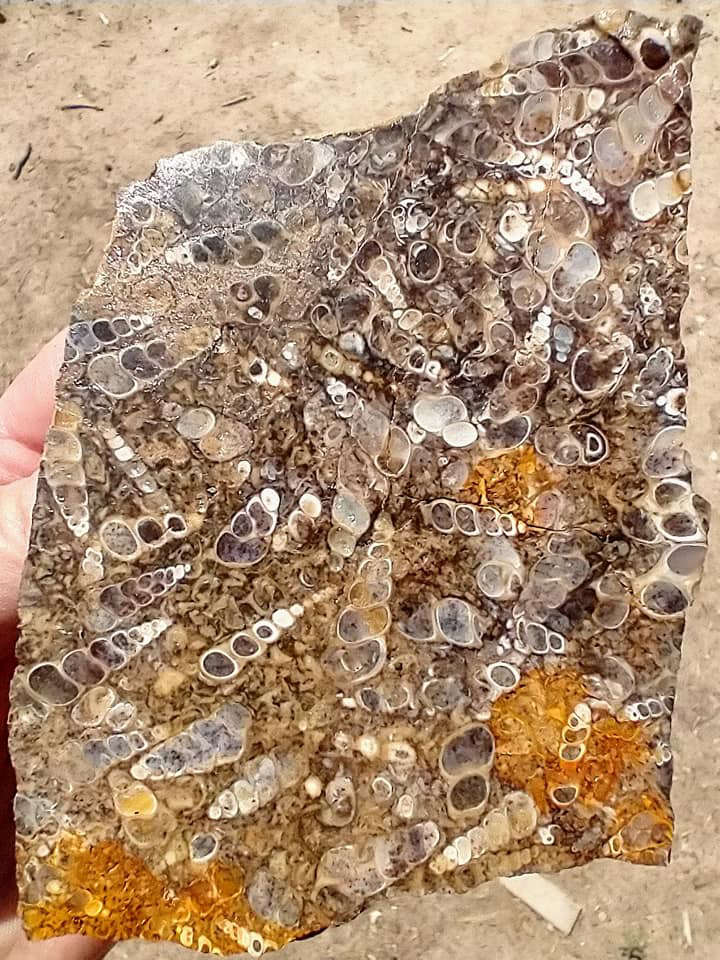

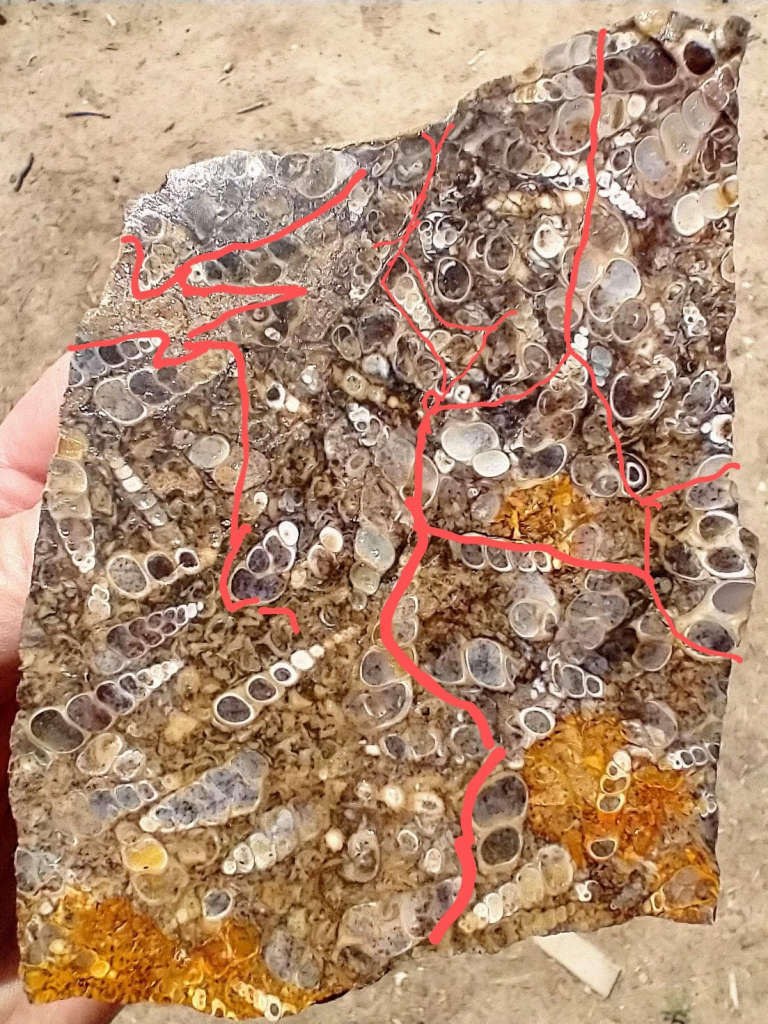

Buying slabs ,minimizes the risk of purchasing low-quality or unusable material since cutting enables a more accurate assessment of the stone’s color and patterns.

Loss when cutting slabs

Purchasing slabs results in reduced waste, as the stone during each saw blade pass corresponds to the blade’s thickness. Additionally, imperfections, cracks, and difficult-to-cut areas like ends contribute to further losses.

The apparent desirability of lapidary rough may be misleading, as it may prove to be worthless once it cut into slabs due to flaws like pitting, soft pockets, as well as poor colors or patterns.

The above example of a slab of Turritella Agate demonstrates the numerus cracks present in the slab. Although the slab may still be utilized to lapidary purposes, the cracks restrict the size and locations where cabochons can be cut.

As a result of the reduced risk and loss in the cutting process, slabs can cost over then times more, if sold by weight, than lapidary rough, and particularly exceptional slabs may be priced substantially higher, if they are put up for sale at all.